The textile industry is undergoing a quiet revolution as smart knitting technologies merge with advanced material science. At the forefront of this innovation lies temperature-sensitive fibers capable of autonomously adjusting garment breathability—a breakthrough that could redefine comfort in athletic wear, medical textiles, and everyday apparel. Unlike traditional moisture-wicking fabrics that rely on passive diffusion, these dynamic textiles physically reconfigure their structure in response to thermal stimuli.

How Temperature-Activated Ventilation Works

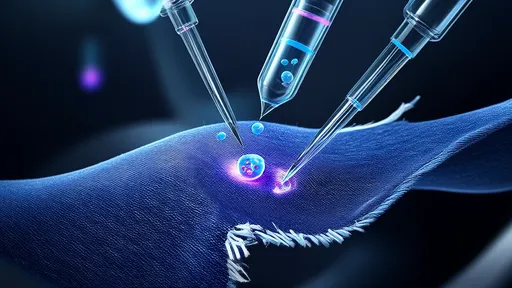

Embedded within the knit structure, shape-memory polymers and liquid crystal elastomers serve as the architectural backbone of self-ventilating fabrics. When body heat reaches a predetermined threshold—typically between 28°C to 32°C—the fibers undergo a molecular rearrangement. This transformation causes strategically placed "micro-shutters" in the fabric to expand, creating ventilation pores that can increase air permeability by up to 300%. As temperatures normalize, the fibers return to their original state with precision rivaling industrial actuators.

The engineering behind these textiles draws inspiration from pinecone hygromorphs and reptile scale morphology. By programming the fiber's phase transition temperature during polymer synthesis, manufacturers can customize activation points for different climates and activities. Arctic expedition gear might only open pores at 35°C, while tropical running shirts could begin ventilating at 26°C. This biological mimicry extends to the pore patterns themselves, with some designs replicating the fractal branching of leaf stomata for optimal airflow distribution.

From Laboratory to Production Lines

Early adopters like Adidas and Under Armour have overcome initial manufacturing hurdles through modified circular knitting machines. These industrial workhorses now integrate thermal profiling cameras that map heat zones during production, allowing for precise placement of smart fibers across stress points (backs of knees, underarms, lumbar regions). The breakthrough came when researchers at MIT's Self-Assembly Lab developed a coaxial spinning technique, encapsulating the temperature-responsive core within a durable nylon sheath—extending functional lifespan to withstand 50+ wash cycles.

Production challenges persist regarding energy-intensive fiber doping processes. However, the recent adoption of photopolymerization techniques has reduced thermal activation thresholds to body-compatible levels without hazardous chemical crosslinkers. This aligns with the industry's push toward sustainable smart textiles, as newer formulations utilize bio-based polycaprolactone derived from plant oils rather than petroleum sources.

The Comfort Algorithm Revolution

Beyond physical porosity changes, leading manufacturers are integrating these fabrics with microclimate management systems. Schoeller Textil's latest prototype embeds thermochromic phase-change materials alongside the ventilating fibers, creating a visual heat map while actively cooling. When combined with humidity-sensing conductive yarns, the system achieves what textile engineers call "four-dimensional comfort"—continuously adapting to temperature, moisture, air pressure, and motion variables.

This multi-stimuli responsiveness addresses a longstanding limitation in sportswear: the delay between perspiration onset and fabric reaction. Field tests with professional football players demonstrated a 40% reduction in core body temperature spikes during high-intensity intervals compared to traditional mesh fabrics. The secret lies in the fibers' sub-second response time—faster than neural thermoregulation pathways can signal sweat gland activation.

Medical Applications Beyond Athletics

Burn care represents perhaps the most transformative application. Researchers at ETH Zurich have developed wound dressings with inverse thermal response—pores constrict when skin temperature exceeds 38°C to maintain sterile coverage while allowing transpiration at safe levels. For diabetic patients prone to foot ulcers, socks incorporating these fibers automatically increase ventilation when localized inflammation is detected, potentially preventing thousands of amputations annually.

Rehabilitation medicine also benefits from the technology's dynamic compression capabilities. Post-surgical garments can now adjust their tightness based on real-time swelling measurements, eliminating the need for frequent manual adjustments. Clinical trials show such smart compression reduces lymphedema treatment costs by 60% while improving patient compliance through automated comfort optimization.

The Sustainability Equation

While smart textiles promise performance benefits, their environmental impact has drawn scrutiny. Traditional temperature-responsive polymers often relied on perfluorinated compounds (PFCs)—the same persistent pollutants banned in waterproof coatings. The industry's response has been twofold: developing biodegradable variants using polylactic acid matrices, and implementing closed-loop recycling systems where spent garments are chemically depolymerized to harvest reusable smart fibers.

Life cycle analyses reveal surprising advantages. A single temperature-adaptive jacket can replace three seasonal garments in moderate climates, offsetting its higher production footprint within 18 months. Moreover, the self-ventilating properties reduce dependence on energy-intensive air conditioning—buildings using smart textile curtains report 15-20% HVAC energy savings in climate-controlled environments.

Consumer Adoption Challenges

Market education remains the largest barrier to widespread adoption. Many consumers conflate the technology with earlier failed attempts at "thermochromatic" fashion that merely changed colors. Brands now emphasize tangible benefits through in-store demo stations where visitors can observe pore dilation under thermal cameras. Price points remain steep at 30-50% premiums over performance fabrics, though economies of scale from military contracts (notably the U.S. Army's Next Generation Soldier Uniform program) are driving costs down.

Perhaps the most unexpected adoption driver comes from an unlikely sector: pet apparel. Temperature-regulating dog jackets have become gateway products, with pet owners more willing to experiment on their animals before purchasing human equivalents. This niche market alone is projected to reach $800 million by 2026, providing crucial R&D funding for broader applications.

The convergence of smart knitting and responsive materials represents more than a textile evolution—it's a fundamental reimagining of clothing's role as an active interface between body and environment. As production scales and complementary technologies like flexible thermoelectric generators mature, we may witness the disappearance of "seasonal" wardrobes altogether, replaced by a handful of endlessly adaptable garments that breathe, insulate, and respond like living tissue.

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025