In a groundbreaking leap for smart textiles, researchers have unveiled liquid crystal fabrics capable of dynamic color-shifting without external power sources. This innovation promises to revolutionize industries from fashion to military camouflage by creating materials that adapt to environmental changes in real time.

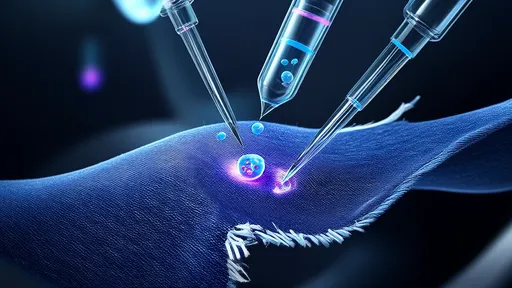

The technology harnesses chiral nematic liquid crystals—the same light-bending structures found in butterfly wings and beetle shells—woven directly into polymer-based fabrics. Unlike earlier color-changing textiles that relied on LEDs or external stimuli, these fabrics achieve autonomous transitions through molecular-level rearrangements triggered by temperature fluctuations.

How does this liquid crystal fabric actually work? At the core of the breakthrough lies a precisely engineered lattice of helical molecules that reflect specific light wavelengths. When ambient temperature shifts, the molecular pitch changes, causing the material to selectively absorb and reflect different colors across the visible spectrum. The effect resembles morphing butterfly wings, but engineered for human-scale applications.

Early prototypes demonstrate remarkable versatility. One military-grade fabric sample transitions from forest green to desert tan within a 15°C temperature range, while a consumer-oriented version cycles through subtle hue variations ideal for mood-responsive fashion. The color shifts occur gradually over 2-3 minutes, creating a mesmerizing organic transition rather than an abrupt digital change.

Durability testing has yielded surprising results. After 500 wash cycles and extensive abrasion tests, the color-shifting properties remained intact because the liquid crystals are encapsulated within protective polymer microcapsules. This addresses a critical weakness of previous smart textiles that degraded quickly with wear and cleaning.

Manufacturing challenges persist, particularly regarding cost-effective mass production. Current methods require specialized looms that can precisely align the liquid crystal threads during weaving. However, several major sportswear brands have already entered partnership agreements, suggesting commercial applications may arrive sooner than anticipated.

The potential applications extend far beyond aesthetic novelty. Architects envision these materials for building facades that regulate heat absorption based on sunlight intensity. Medical researchers are exploring how color-changing hospital gowns could visually indicate patient temperature fluctuations. Even automotive designers are prototyping seat covers that change color to warn drivers of icy road conditions.

Environmental considerations have been central to the development process. Unlike conventional dyes, these liquid crystal fabrics require no water-intensive coloring processes. The self-illuminating nature of the technology could theoretically reduce fashion industry dye pollution by up to 17% if widely adopted.

As with any disruptive technology, questions remain about consumer acceptance and practical limitations. Can the color range be expanded beyond current thermal response parameters? How will the material perform in extreme climates? These are the challenges now being tackled in laboratories across three continents.

The team behind the innovation emphasizes that this represents just the first generation of autonomous color-shifting textiles. Next-phase development focuses on incorporating multiple stimuli responses—where fabrics could react to both temperature and humidity changes simultaneously—and exploring photovoltaic integration to enable even more dramatic transformations.

Industry analysts predict the global market for dynamic textiles could reach $5 billion by 2028, with liquid crystal fabrics capturing at least 40% of that share. As patents are filed and production scales up, we may soon witness a world where clothing becomes as responsive to its environment as living organisms.

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025